Maximize your logistics savings, visibility, and efficiency

Harness Uber Freight's AI-led enterprise suite of solutions backed by more than two decades of industry data, technology, and hands-on partnership.

TMS

3PL & 4PL

Cross-border

Intermodal

Over the road

End-to-End

Small business freight

AI tech

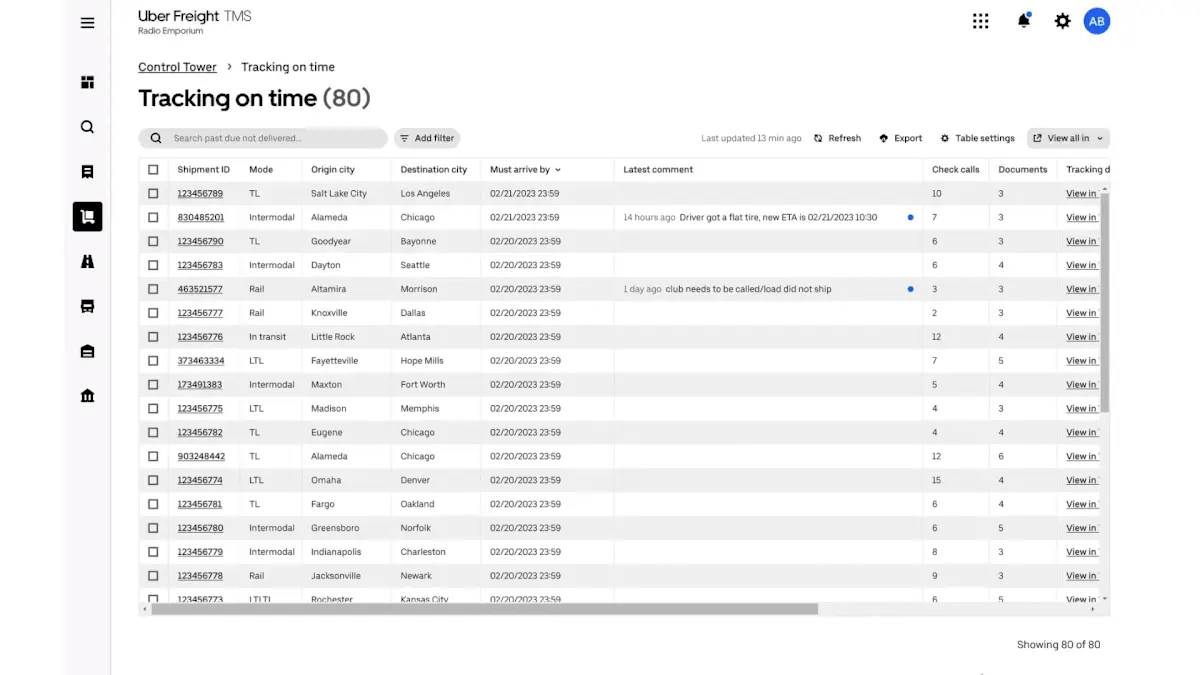

Uber Freight TMS

Since 2005, leading brands have trusted Uber Freight TMS to streamline their operations end-to-end, from procurement and execution to visibility and payments. Save time and money by improving your network while gaining visibility, foresight, and control across shipments.

Logistics-specific data at scale

Over the past two decades, Uber Freight has built and refined one of the most comprehensive logistics data ecosystems in the industry, from overseeing 20B+ freight under management and supporting one in three Fortune 500 companies.

We’ve also cleaned and processed metadata from 100+ distinct sources, including our massive carrier network, Uber Freight TMS, and Mexico cross-border operations—for a level of data depth and diversity few others can claim.